Ladle Transfer Cars

Price 500000 INR/ Unit

MOQ : 1 , , Unit

Ladle Transfer Cars Specification

- Usage

- For Construction Use

- Condition

- New

- Product Type

- Ladle Transfer Cars

- Power Source

- Electric

- Width

- 20-30 Millimeter (mm)

- Voltage

- 220 Volt (v)

- Feature

- Durable

- Warranty

- 1 Year

- Attributes

- Rust Proof, Strong, Durable, Easy To Operate

Ladle Transfer Cars Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 3 Units Per Month

- Delivery Time

- 1-2 Week

- Main Domestic Market

- All India

About Ladle Transfer Cars

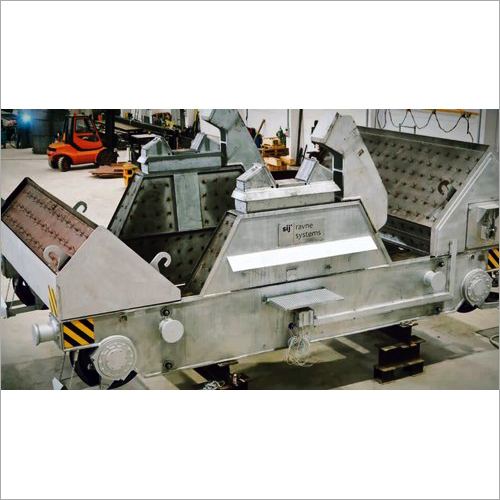

Ladle transfer cars, also known as ladle transporters, are specialized vehicles used in steel plants and foundries to transport ladles filled with molten metal or other hot materials. They provide a safe and efficient method for moving ladles between different areas of the production facility.

Frequently Asked Questions :

Q: What is the purpose of a ladle transfer car?

A: The primary purpose of a ladle transfer car is to transport ladles filled with molten metal or other hot materials within a steel plant or foundry. They ensure the safe and efficient movement of ladles between different areas, such as the furnace, casting stations, and storage areas.

Q: How do ladle transfer cars work?

A: Ladle transfer cars are equipped with specialized platforms or cradles that securely hold the ladles. They are typically powered by electric motors or hydraulic systems and can be operated manually or remotely. The ladle transfer car moves along designated tracks or rails, allowing for precise positioning and controlled transportation of the ladles.

Q: Where are ladle transfer cars used?

A: Ladle transfer cars are extensively used in steel plants, foundries, and other metal production facilities. They play a crucial role in the transportation of molten metal from the furnace to the casting stations, ensuring a continuous and efficient production process.

Q: What are the advantages of using ladle transfer cars?

A: Ladle transfer cars offer several advantages in the steel and foundry industry. They enhance safety by providing a controlled and secure method of transporting hot ladles, minimizing the risk of accidents or spillage. They also improve operational efficiency by reducing the time and effort required to move ladles manually.

Advanced Durability and Strength

Constructed using high-quality, rust-proof materials, our Ladle Transfer Cars are built for resilience in challenging construction settings. Their robust composition ensures longevity and strength, even under rigorous daily usage. The focus on durability means less maintenance and reliable performance throughout their operational life.

Effortless Operation and Safety

Ease of use is central to these transfer cars. With a straightforward electric-powered control system, operators achieve precise, safe transportation of heavy ladles. The design incorporates enhanced safety features to reduce risk and streamline construction workflow, making it ideal for both experienced and new operators.

FAQs of Ladle Transfer Cars:

Q: How are Ladle Transfer Cars typically used in construction projects?

A: Ladle Transfer Cars are primarily employed to transport molten materials or heavy components across different areas of a construction site safely and efficiently. Their robust design and powered mobility make them indispensable for handling demanding tasks in industrial and construction environments.Q: What benefits does the rust-proof and durable design provide?

A: The rust-proof and durable construction ensures the Ladle Transfer Car withstands harsh site conditions and resists corrosion, leading to extended service life and reduced maintenance. This reliability helps minimize downtime and supports continuous operation.Q: Where can these Ladle Transfer Cars be supplied from and to?

A: Manufactured in India, these transfer cars are available for domestic distribution and export. We supply to a wide range of clients, including construction companies, manufacturers, and suppliers across the globe.Q: What is the process for operating these Ladle Transfer Cars?

A: Operating the Ladle Transfer Car involves a simple electric-powered control system. Users can move heavy loads by activating intuitive controls, enabling smooth and accurate transportation with minimal training required.Q: When is the ideal time to use a Ladle Transfer Car on-site?

A: Ladle Transfer Cars should be utilized during tasks requiring the safe, quick movement of substantial materials or ladles, particularly when efficiency and safety are critical, such as during high-volume construction or material handling operations.Q: How does the one-year warranty benefit users?

A: The included one-year warranty provides peace of mind by covering manufacturing defects and performance issues, helping customers reduce financial risk and ensuring reliable operation throughout the coverage period.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Transfer Cars Category

Billet Transfer Cars

Price 400000 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Voltage : 220 Volt (v)

Usage : For Construction Use

Power Source : Electric

Ladle Sequencing Cars For Concast

Price 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Voltage : 320 Volt (v)

Usage : For Construction Use

Power Source : Electric

Transfer Car

Price 500000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Condition : New

Voltage : 220 Volt (v)

Usage : For Construction Use

Power Source : Electric

Loco For Hauling Quenching Car, Torpedos

Price 1500000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Condition : New

Voltage : 220440 Volt (v)

Usage : For Construction Use

Power Source : Electric

SHIVA FERROUS PVT LTD

GST : 19AAECS5205L1Z5

GST : 19AAECS5205L1Z5

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS